Custom bottle manufacturer | Glass Jar Packaging | Glass perfume bottle manufacturer

Custom Bottle Packaging Solution

Anitarpak is a professional custom glass bottle manufacturer specializing in cosmetic, skincare, perfume, food, and pharmaceutical packaging. We provide luxury-grade glass containers with full customization—shape, finish, closure, and sealing solutions.

Custom Glass Cosmetic & Perfume Bottles Packaging Manufacturer

At Anitarpak, we believe glass packaging represents more than protection — it’s a statement of quality, purity, and brand value.

Our glass bottles and jars are designed for high-end cosmetic, skincare, fragrance, nutraceutical, food, and pharmaceutical applications, offering both luxury aesthetics and reliable performance.

We provide custom design, precision mold development, and surface finishing tailored to your product’s personality and market positioning.

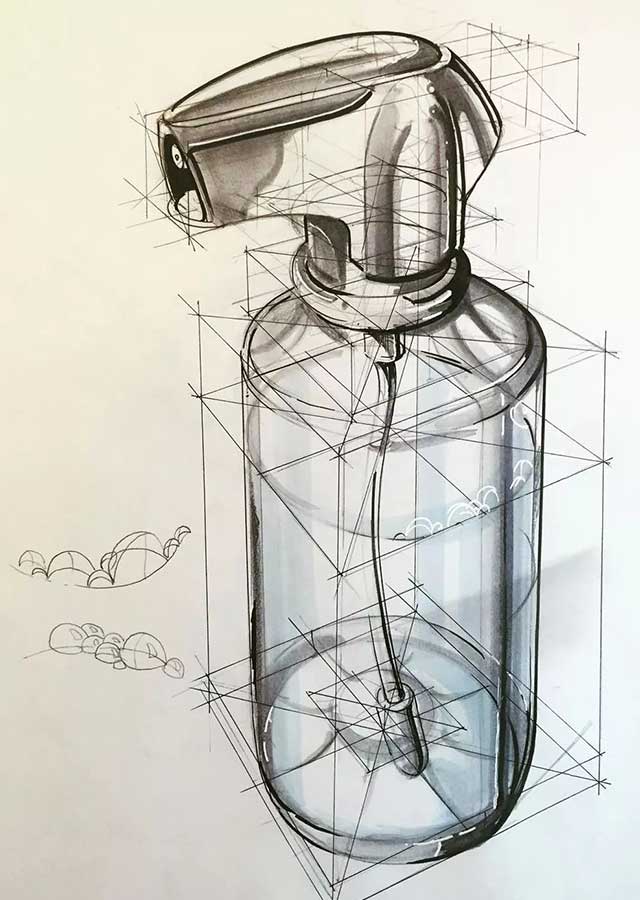

Fully Customized Solution

At Anitar, we understand that every brand has a unique identity — and your packaging should reflect it. We offer fully customized bottle and container solutions to help you stand out in a competitive market.

Shape Customization

Round / Square / Oval / Polygonal / Special-shaped Bottles

Material Options

High-clarity Glass, PET / PE, Acrylic, Aluminum / Metal, Bio-based Plastic

Surface Finishing

Frosting/Matte Finish, Color Spraying/Gradient Painting, Screen Printing/UV Printing

Sealing Components

Screw Caps, Pump Dispensers, Droppers & Pipettes, Flip-top/Disc Caps, Child-proof Closures

Size & Volume

Glass Bottles: 10ml – 500ml Plastic Bottles: 30ml – 1000ml Jars & Containers: 5g – 500g

Outer Packaging

Individual Inner Boxes, Customized Paper Sleeves / Gift Sets

💄 Cosmetic & Fragrance Packaging

Pain Points:

·Need for unique packaging design to reflect brand DNA

·Fragility during transportation

·Matching tolerance with pumps and closures

·MOQ and development lead time

Our Solutions:

·Custom mold design based on your 3D concept or sketch

·Impact-resistant reinforced glass formulation

·Thread and neck precision matching (GPI, DIN standards)

·Low MOQ custom color and finish options

·Fast prototype and sampling in 10–15 days

Glass cream jars

Glass lotion bottles

Serum and essence bottles

🍯 Food & Beverage Packaging

Pain Points:

·Safety and contamination prevention

·Container sealing strength under transportation

·Regulatory compliance for food contact

Our Solutions:

·Food-grade soda-lime or borosilicate glass

·Advanced annealing process to enhance mechanical strength

·FDA & EU-compliant materials and test reports

Glass Honey jars

Glass Beverage bottles

Glass Diffuser bottles

Glass spice jars

🍃 Nutrition & Supplement Packaging

Pain Points:

·Compatibility with automatic filling and capping machines

·Packaging contamination risks

·Tight delivery schedules for high-volume production

Our Solutions:

·High-precision neck threads for fast capping and sealing

·Cleanroom-grade production environment

·Fast mold turnover and 24/7 production lines

Amber or green glass pill bottles

Glass jars for gummies or soft gels

capsules or powders Glass containers

💊 Medical & Pharmaceutical

Medicine vials

Dropper bottles

Tincture and sample glass containers

Luxury Packaging Manufacturer

Where We Build Your Visions

Xiamen Anitar Display Co., Ltd. is a professional packaging manufacturer based in Xiamen, Fujian Province. We specialize in providing complete packaging solutions — including product development, mold design, manufacturing, and sales services.

With an experienced engineering, sales, and service team, we offer strong capabilities in independent design and innovation. Our production workshop meets national purification standards and is certified at the 100,000-level cleanroom standard.

Our products are widely used in the cosmetics, chemical, and food industries. Over the years, we have earned a solid reputation for consistent quality, reliability, and customer trust.

- Call Us Today

+1 6319866116

Request a Quote

Quick Answers to Common Customer Questions

Everything You Need to Know

1.Your company type

2.What industry products are your packaging materials used in?

3.Confirm the capacity, color, surface treatment process, quantity, and customized packaging requirements of the container

4.What is your expected delivery time

5.Please provide us with your company name, phone number, and email address

6.Our cooperation process:Sample → Production → Delivery

👉 For standard models: 1,000–3,000 pcs.

For full customization: depends on mold design and color requirements.

✅ Yes! We support low MOQ and mixed-model orders for new brands.

⏱ Regular orders: 15–25 days after confirmation.

Custom molds or decoration: 30–40 days.

🎨 Yes. Our in-house design team can help with artwork, label layout, and print files.

🧴 All materials are FDA, EU, or ISO compliant and BPA-free.